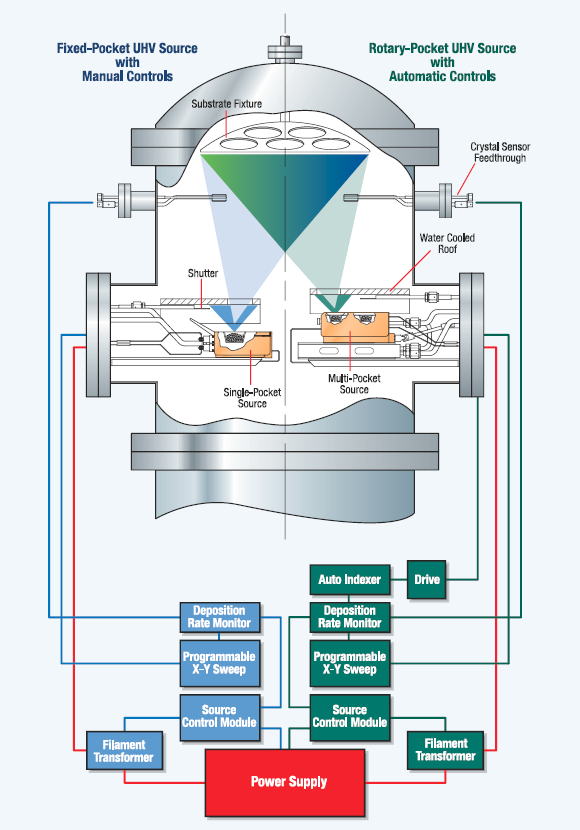

While E-beam can be used for production where multiple substrates are coated simultaneously. Effusion cell is used for single substrate. In both cases, the target material is heated by either hot filament or an e-gun.

E-beam can go up to 3,000 degree Celsius . OUr beam is shaped and directed towards the target at exactly 90 incident angle. This is critical in the performance of an e-beam system.

When deposit metal onto substrate, DC power is used. When deposit dielectric material, F power and matching network is used.

RF Applications:

Nitride and Oxide are dielectric materials.

Optoelectronics (LED…)

Super conductor

PV, RF devices

Hi bandgap semi

Optical Nitrogen doping: Photovoltics (CdTe…) Oxygen doping: III-V materials

Available control modules:

RF generator

Ion deflection

Plasma monitor/diagnostics/Flux control

Ion extraction grid for ion beam assisted growth

Matching network auto tune

Gas handling and control

E-Beam & Sputtering system

Features and Benefits:

- Chamber size up to 40″ diameter x 60″ high

- Up to 8 target materials

- Co-evaporation

- PC/ PLC architecture

- Rotating/ Tilt substrate holder

- 16kW IR heater

- Automatic or manual operation

Process Optimization

- Higher deposition rates

- Thickness uniformity optimization

- Stoichiometry uniformity control

- Process chamber configuration

- Standard settings for many app.