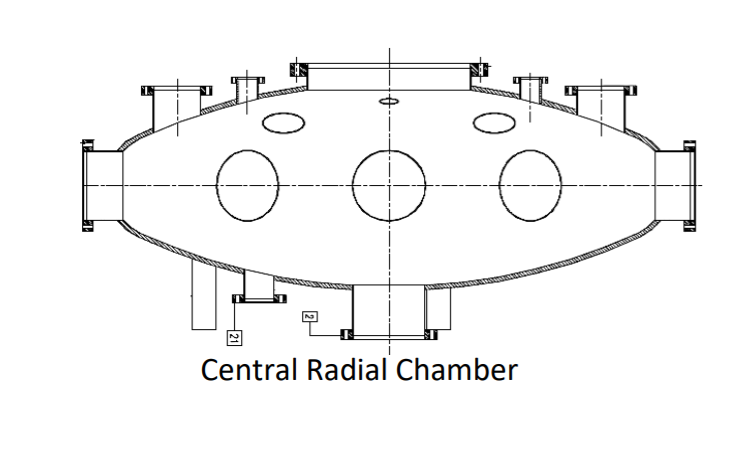

There are two common type of transfer systems: Linear and Radial. While Linear system has nearly unlimited scalability, the Radial system is used where small footprint is critical.

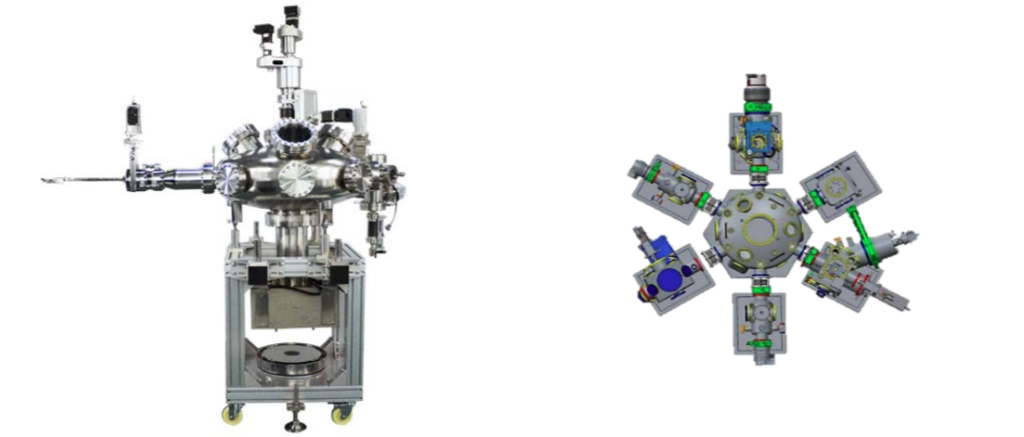

Radial Transfer System

The Radial transfer System is hosted in an UFO-shaped chamber. UFO is used in multi-process applications. It allows a sample to go through many different processes and analysis “in-situ” without being exposed to atmosphere, thus eliminates any chance of potential contamination.

Up to 8 sub-systems can be connected to the UFO. Our UFO is equipped with transfer mechanism that extends up to 820 mm from port edge.

Features

| Base Pressure | <5 x10^10 mbar |

| Capacity | up to 8 sub-systems |

| Stroke | 820mm measured from port edge |

| Actuation | Manual or motorized |

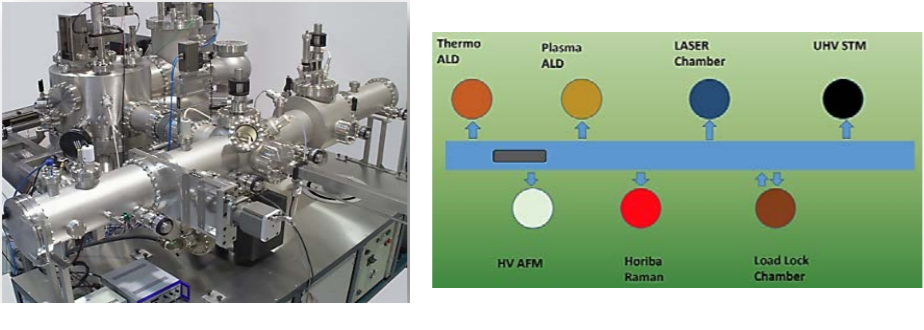

Linear Transfer System

- Unlimited transfer distance via extensions

- Movable trolley holds up to 12 samples

- Trolley on a stainless steel track in vacuum

- Trolley is magnetically coupled to transporter (outside the vacuum)\

- Buffer module to house process chambers and analysis

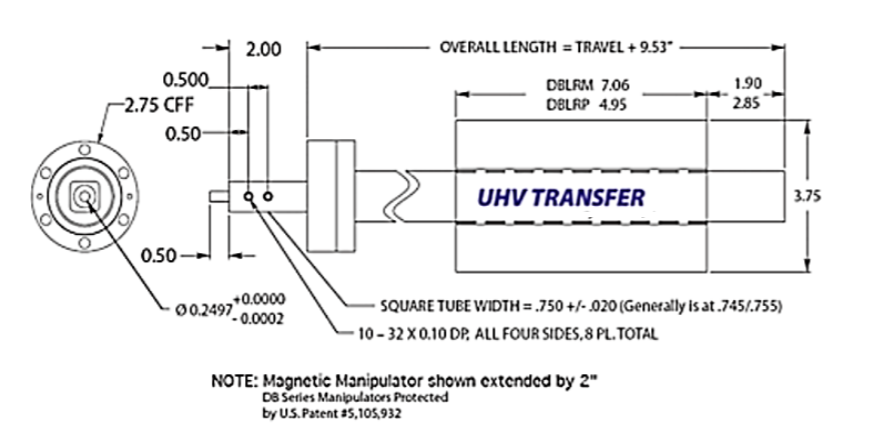

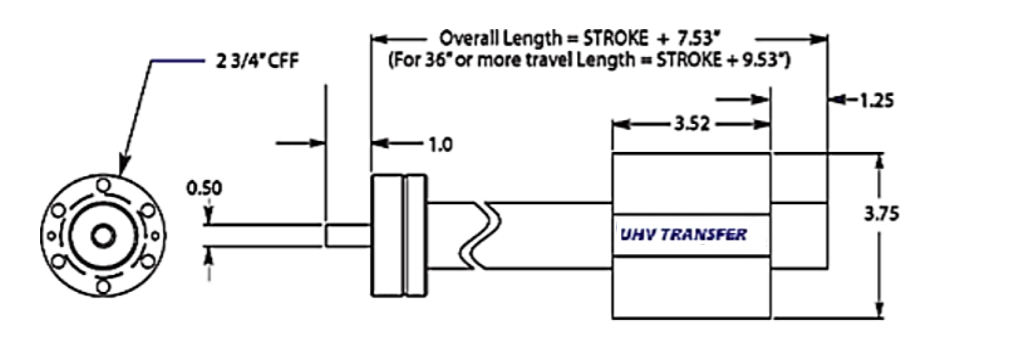

Magnetic Transporter for UHV

Magnetic Transporters are devices to introduce a sample into a vacuum chamber without breaking vacuum. Motion is achieved by use of magnets outside the vacuum to manipulate the mechanism inside the vacuum. The unique (patented) design of our heavy-duty transporters use a strong square hollow shaft instead of a round shaft providing very high performance. Traditional single shaft transporters are also available.

Product advantages:

- Higher rigidity

- Longer extension without sagging

- Higher decoupling force

- Built-in 2nd operation for lift, etc

- Higher precision

Models for magnetic transporters:

| VFMS | Linear only; single shaft a heavy duty square shaft. |

| VFMD | Linear + rotary; dual shaft a round shaft inside a heavy duty square shaft |

| VFML | Linear and/or Linear+rotary; single shaft uses single round shaft |

VFMS and VFMD perform better than competition due to the use of heavy duty square shaft. Higher rigidity allows linear extension beyond 160″ in vertical position and 60″ in horizontal with little sagging.

VFMD construction has a round shaft that rotates inside a square hollow shaft. Two shafts working independently allowing secondary operation such as clamping , lifting, rotation, lock and rotate stages which make them the best on the market. Conventional design uses a single round shaft for both axis.

VFML is designed for light duty. It is based on conventional design (single round shaft) at a greater savings.

All magnetic transporter have the following features

| Actuator Housing | Anodized Aluminum |

| Magnets | NdFeB |

| Vac. Range | 1x 10^11 Torr |

| Bake Temp | 250°C (carriage removed) |

Square Shaft Magnetic Transporters

Dual Shaft

VFMD-LRM : Linear + rotary, metal bearing

VFMD-LRP : Linear + rotary, polymeric bushing

Single Shaft

VFMS-LM : Linear + rotary, metal bearing

VFMS-LP : Linear + rotary, polymeric bushing

Metal bearing is ideal for applications where excellent tactile feedback is desired or for high duty-cycle use. Carriages glide on polymeric bushings (outside of vacuum) are for use where a slight stiction is preferred.

Linear + Rotary, VFMD-LRM, VFMD-LRP

Specifications:

| Linear Compliance: | 0.0035 in/lb |

| Linear Decoupling | 26 lbs |

| Rotary Torque | 12 in-lbs |

Pneumatic and Motor drive available

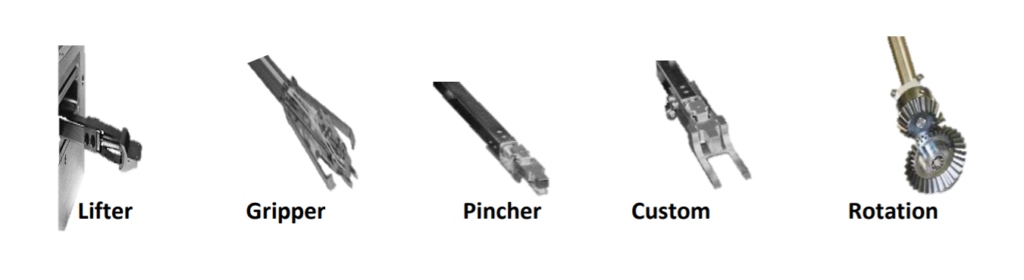

Manipulator End Effectors

Numerous end-effectors are available for Magnetic Transporters. The independent motions of the VFMD-LR manipulators allow the rotation of the inner shaft to operate a cam for vertical lift, flex a gripper, open/close a pincher, rotate gear-box

Single square shaft Linear only, VFMS-LM, VFMS-LP

Specifications:

| Linear Compliance: | 0.0025 in/lb |

| Linear Decoupling | 26 lbs |

Pneumatic and Motor drive available

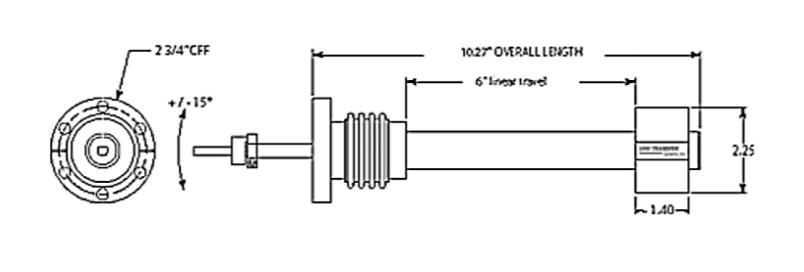

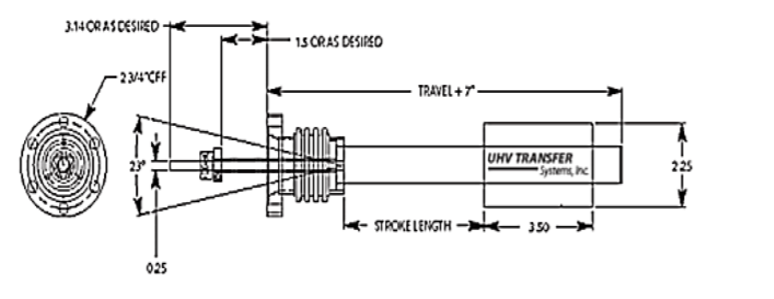

Round Shaft Magnetic Transporters

Lite Duty, with round shaft Lite duty transporter, VFML

In addition to Square shaft, we also has the conventional round shaft design for the lite duty application at a cost saving.

Linear + Rotary

VFML-LRP : with polymeric bushing

VFML-LR: Single round shaft magnetic manipulator is ideal for simple transfers requiring linear and/or rotary motion. It is less expensive than VFMD, and it offers superior linear force and torque to that of other conventional manipulators.

Specifications:

| Linear Compliance: | 0.0035 in/lb |

| Linear Decoupling | 26 lbs |

| Rotary Torque | 12 in-lbs |

Pneumatic and Motor drive available

Wobble stick, VFML-WS

Magnetically-Coupled Transfer Sticks are an economical way to perform simple linearangular motion within a vacuum system. They are robust and reliable reducing the risk of leaks by eliminating the use of edge welded bellows. Rare earth magnets “outside of vacuum” provide a strong magnetic coupling. With the external magnet carriage assembly removed, it is bakeable to 250°C. Standard Transfer Sticks are available with up to 12 inches of push-pull linear travel and an angular tilt of ± 11 degrees.

Specifications:

| Actuator Housing | Anodized Aluminum |

| Magnets | NdFeB |

| Vac Range | 1 x 10^11 Torr |

| Linear Decoupling | 4 lbs |

| Angular Movement | +/- 11 degrees |

| Flange | CF2.75 |

Linear only – VFML-WS-L

Linear + Rotary – VFML-WS-LR

HV/UHV Loadlock and Transfer Systems

High-vacuum compatible loadlocks are designed to load wafers or other substrates into a SEMI standard or custom process module. Using magnetically coupled transfer devices, wafers or other substrates can be repeatedly loaded and removed without breaking vacuum. Chambers are available for wafers or substrates up to 200, 300 or 450mm. Loadlock systems can be manually operated and motorized. Customized systems are available.

Typically a loadlock is mounted to a gate valve attached to a main system chamber. Position a substrate in through the loadlock door. After the loadlock is evacuated to the desired vacuum level, the gate valve would be opened and the substrate transferred into the chamber for processing. This allows repeated substrate loading/unloading without breaking vacuum greatly reducing process time.

Manual Transfer – Single-Wafer Loadlock System

The MASCOT can mimic the motions of a complex and costly robot but is convenient to use and significantly less costly. Chambers are available for wafers or substrates up to 200, 300 or 450 mm. Optional items available are vertical lift capability, heavy-duty cart for portability and limit switches.

A linear-only transporter (VFMD-L) will precisely transfer a substrate into a process chamber where the receiving station has vertical lift capability to remove the substrate from a carrier on the end of the manipulator. The carriage rotation (VFMD-LR) is used to operate a dynamic end effector with vertical motion to lift or lower a substrate onto the receiving stage for processing in a chamber without lift function. The VFMD returns to lift the substrate and withdraw it into the loadlock chamber after processing is complete.

Specifications:

| Material | Chamber: Machined from solid Alum block HV compatible; viton o-rings |

| Magnetic Transporter: All UHV compatible | |

| Substrate Sizes | 100mm, 300mm, 450mm or custom |

| Pump port | ISO NW100 (4″ ID) |

| Auxiliary Ports | Three ISO NW40 (1.57″ ID) |

| Transfer Distance | Up to 60 inches |

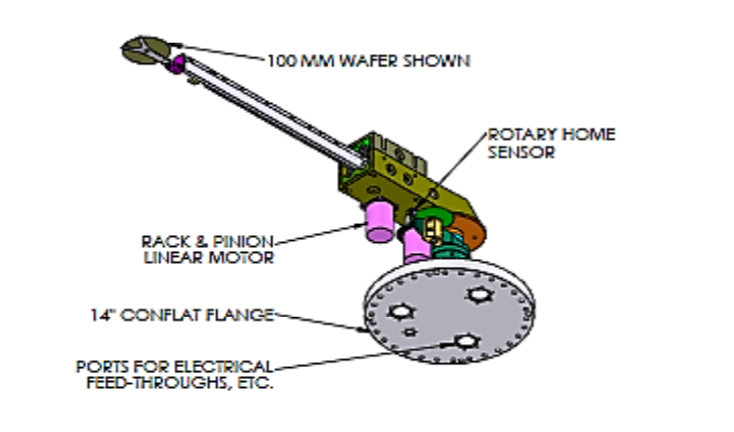

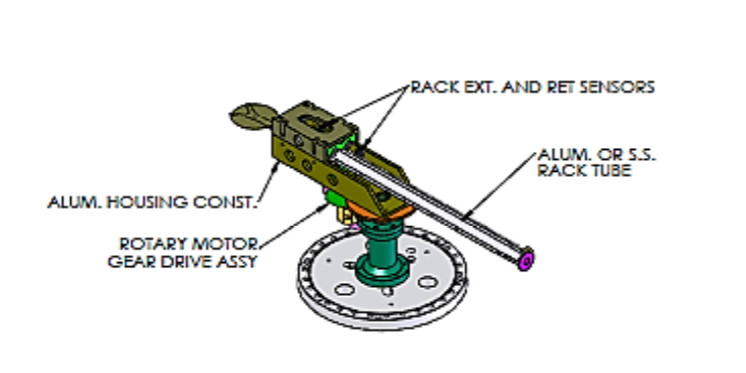

Automated Transfer – Single Wafer Loadlock System

The TEAM-Mate is a compact, single-substrate loadlock system with a magnetially-coupled slide mechanism powered by an exterior stepper motor driven stage. The system comes with stepper driver and power supply with communications link and end point limit switches. A unique design with moving parts located well below transfer mechanism, minimizes particulates. Incorporating the transfer device into the chamber wall reduces the system’s overall footprint. Applications include process development and a manufacturing tool

Specifications:

| Material | Chamber: Machined from solid Alum block HV compatible; viton o-rings |

| Substrate Sizes | 100mm, 300mm, 450mm or custom |

| Pump port | 200mm (ISO NW40) 300mm (ISO NW64) 450mm (ISO NW100) |

| Auxiliary Ports | Two or Three, size: Chamber dependent |

| System I/O | Push button, RS232 or digital I/O |

| Transfer Distance | Varies by substrate size |

Radial transfer System, custom